As pure water is evaporated, minerals are left behind in the recirculating water. As evaporation continues, the water becomes more concentrated than the original make up water. This eventually can lead to saturated conditions. The term cycles of concentration compares the level of solids of the recirculating cooling tower to the level of solids of the original raw make up water. If the circulating water has four times the solids concentration than that of the make up water, then the cycles are 4. Bleed off is the process of removing a portion of concentrated recirculating water, which is obviously replaced with fresh make up water. By specifying a certain amount of bleed off we limit the cycles of concentration the system can operate at, thus controlling scale formation. Various treatments will let us operate at various cycles depending on the make up water analysis and heat loading of the tower. Bleed off is critical to a successful treatment program. The preferred method of bleed off control is with the use of automated bleed off control. This includes a contacting head water meter, dual timer, chemical pump and solenoid controlled bleed off line. A) Evaporation Loss: from a cooling tower (E) = .001 (Cr) (DT) where Cr = circulation rate in gallons per minute and D T = temperature differential between hot and cold water in °F. The evaporation rate amounts to 1% of the recirculation rate for every 10°F DT. B) Windage Loss: This is a relatively small amount of entrained water lost as fine droplets in the air discharge from a tower. Unlike evaporation which does not contain dissolved impurities windage carries these impurities with it and reduces dissolved solids in the circulating water. Typical values are 0.1% to 0.3% of the circulating rate for mechanical draft towers. C) Bleed off: In the evaporation process the non volatile impurities in the make up water are concentrated. To prevent excessive concentration some of the circulating water must be removed from the system. This is commonly referred to as bleed off or blowdown. The amount of bleed off can be determined from the following equations: % B (bleed off) + % (windage) = % E (evaporation loss) / ( cycles -1) D) Cycles: The previous equation added a new turn to the mix . CYCLES!!!!!!!! This is one of the most difficult terms to understand. I will now attempt to define cycles of concentration. The NACE defines it as: A measure of the degree to which dissolved solids are being concentrated in the circulating water. It is in effect the inverse of blowdown. As pure water is evaporated all of the solids are left behind so they concentrate in the cooling tower water. If we start out with fresh water the tower has one cycle of concentration. When all the fresh water is evaporated ( solids are still in the tower) the tower then refills itself with more fresh water and we have twice the solids in the tower. We now have two cycles of concentration. This process will proceed and scale will form at a certain point. We use bleed off to prevent the tower from reaching the point of scale formation. In an actual tower, this is an ongoing process with continuous addition of make up water and continuous bleed off. The allowable cycles of concentration will be determined by the laboratory. They are based on water analysis, heat transfer rate of the equipment, and feed equipment present. We normally use chloride to determine the number of cycles a tower is operating at. The following equation can be used for this calculation: Chlorides in tower water / Chlorides in make up water = Cycles of concentration For example, a tower operating at a 450 gallons per minute recirculating rate (Cr) , 5 cycles of concentration, 10° DT, and 0.1% windage loss: %B + .1% = 1% / (5-1) which is %B = .25% - .1% therefore %B = .15% of the circulating rate. %B = 0.15% ( 450 gallons/minute) which is 0.675 gallons of bleed off /minute. Total make up water requirements for the system are: Bleed

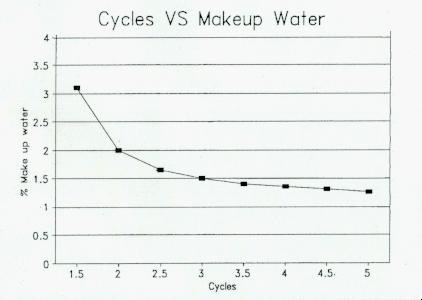

off 0.675 gallons per minute Total make up water = 5.625 gallons/minute Total make up water per hour is = 60 minutes/hr. ( 5.625 gallons per minute) = 337.5 gallons per hour. As you can see the higher the cycles the less make up water and blowdown are required. This is true to a certain point where additional cycles do not decrease the amount of make up water and blowdown as drastically. The following graph illustrates the point. As you can see at about 4.5 cycles the curve starts leveling off which indicates higher cycles will not effect the quantity of make up water drastically.  |

|

|

Hydro-Logic Incorporated 340 South Broadway Gloucester City, NJ 08030 Phone: (856) 742-8300 Fax: (856) 742-7623 |

Website Designed & Maintained by LightHouse Marketing |